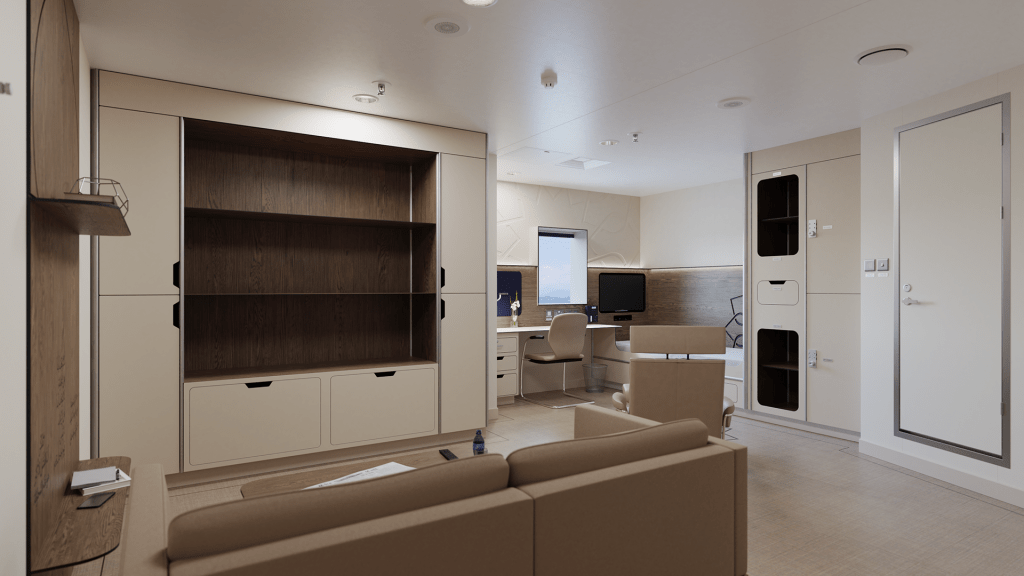

A fitted furniture story

Geschwender is the leading manufacturer of offshore living accommodation furniture.

A fitted furniture story

Geschwender is the leading manufacturer of offshore living accommodation furniture.

A fitted furniture story

Geschwender is the leading manufacturer of offshore living accommodation furniture.

A fitted furniture story

Geschwender is the leading manufacturer of offshore living accommodation furniture.

A fitted furniture story

Geschwender is the leading manufacturer of offshore living accommodation furniture.

A fitted furniture story

Geschwender is the leading manufacturer of offshore living accommodation furniture.

A fitted furniture story

Geschwender is the leading manufacturer of offshore living accommodation furniture.

A fitted furniture story

Geschwender is the leading manufacturer of offshore living accommodation furniture.

A fitted furniture story

Geschwender is the leading manufacturer of offshore living accommodation furniture.

A fitted furniture story

Geschwender is the leading manufacturer of offshore living accommodation furniture.